ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn morePredator Printer Applicator

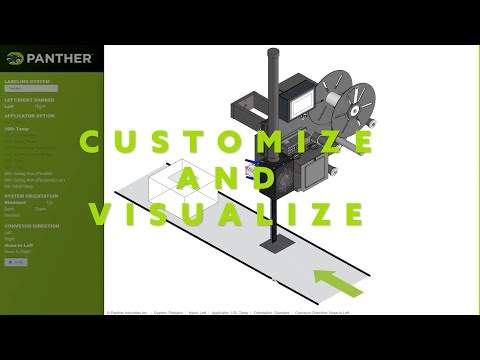

Hi, I'm Steve Finn, Director of Sales and Marketing for Panther Industries. In this video, we'll highlight the key features and benefits of our all-electric labeling automation system, the Predator.

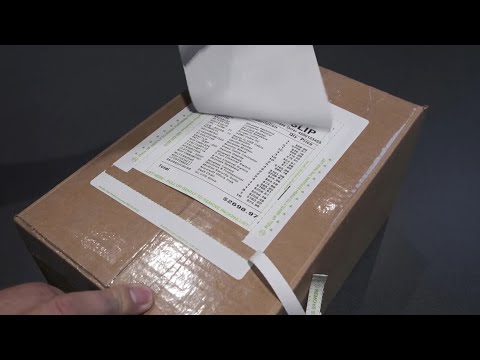

The Predator offers incomparable applicator speed for top apply label applications, up to 200 inches per second, maximizing throughput in your e-commerce distribution or fulfillment operations. To boost your labeling automation output, integrate multiple Predator systems in line with each other and watch your throughput really accelerate. Being an all-electric system, there is no need for compressed air, reducing utility costs for your facility.

The Predator features an adaptive applicator that automatically adjusts to carton sizes to ensure accurate and consistent label placement while variable height items are in motion. With our adaptive touch technology, the tamp provides a light touch during the label application process. The Predator can reach label application distances up to 58 inches for our straight tamp and 24 inches with our carbon fiber swing arm.

With OEM print engine integration from either Zebra, Sato, or Honeywell, the Predator can be custom configured to align with your specific print engine requirements. Built for speed, accuracy, and reliability, the Panther Predator will increase your throughput, reduce your expenses, and decrease waste or loss for your business.