ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn morePrint & Apply

Samples of Panther printer applicators applying labels to packaging.

The Panther Phantom is the evolution of label automation uptime. Featuring numerous applicator options, this system can be custom-configured to address your specific requirements to achieve maximum throughput.

A compact, pneumatic printer applicator for on-demand printing solutions that features configurable applicators for your case, flat item, packaging, and product labeling and barcode needs.

An entry-level on-demand labeling solution for greater integration into your growing operation.

Whether it is a result of non-performing equipment, the need for additional production lines, or addressing manual procedures when preparing your outbound items, your bottom line could benefit from a boost in throughput.

Increase throughput and efficiency with tandem Predator Printer Applicators for your flat items and packaging needs.

A specialty print and apply labeling solution for mail-order pharmaceutical labeling.

Utilize our blow-on applicator for situations where direct contact with a product is not ideal, such as food, light/delicate items, or padded shipping envelopes.

Whether your company requires labeling of bags that are filled or flat, the application to this type of item presents numerous challenges. And in certain instances, you may require both a pre-printed and print-on-demand label applied to your bag.

With a tamp blow applicator, the applicator extends in close proximity to the item (without contacting it), and then the label is blown onto the surface via a pneumatic system.

Using our Wipe Applicator, labels are wiped across the surface of the item as it passes by the applicator, typically in extreme, high-paced labeling operations.

Our merge applicator features a brush or wrap option that directly applies a pre-printed label to a product or carton. Designed for applications where speed and accuracy are critical.

Our Tamp Applicator can not only label flat surface items but can also be used in some cases where a partial wrap may be needed on larger products.

Utilize our Tamp Applicator for flat item labeling automation for mailers and specialty bag labeling.

For pre-printed corner wrap or security tab labeling, our corner wrap capabilities allow you to label your product packaging efficiently and accurately.

The swing blow applicator features a swing arm that presents the label prior to application on the front, side, or top of an item. The label is then blown onto the surface with minimal contact from the applicator surface.

The merge applicator is used to apply pre-printed labels to packaging. This label applicator features increased throughput, reliability, and durability for diverse product requirements.

Our PharmaFold solution applies a secondary label that “flags” from the side of a bottle without covering the primary label. This additional label can provide patient information or additional instructions related to the prescription.

Our PharmaWrap labeling automation solution wraps a primary label around the curved surface of the bottle, consistently and accurately every time.

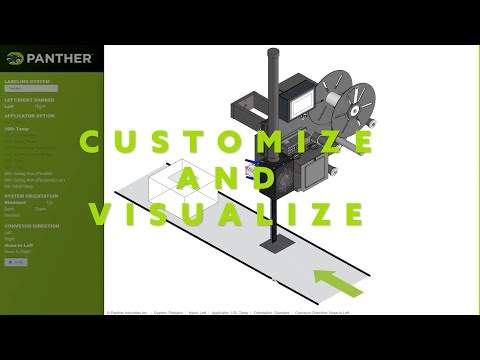

Plan, customize, and visualize your Panther labeling automation system with the Panther Virtual System Builder.