FLEXible Configurations +

Budget FLEXibility

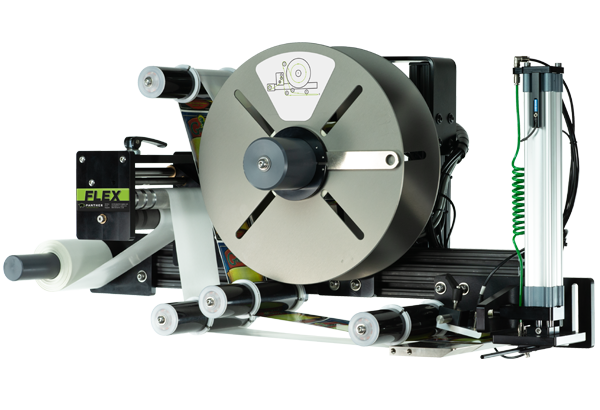

Introducing the new Panther FLEX – the economical and FLEXible pre-printed label applicator. Built for ultimate affordability and versatility, the entire system is engineered around a reconfigurable backbone that allows for horizontal, vertical, or custom arrangements – perfect for your specific application or spatial requirements.

The FLEX provides the ultimate FLEXibility, both for your operations and your budget. Engineered to be manufactured in either a horizontal or vertical arrangement to provide a perfect fit within your specific environment.

Key Features

- Reconfigurable to fit within tight/small spaces

- Feed speeds up to 18 IPS

- Dual automation options (full or semi)

- Zero waste pneumatics – only uses air during operation

- Improved label drive system for easy load capability

- Remote mounted control box w/ 4″ touch screen display

- Movable gap sensor for easy label calibration

Product Overview:

Increase Throughput

Faster fulfillment speeds within the same or smaller footprint.

- Perfect for tight or limited space installations.

- Reconfigurable backbone that allows for vertical or horizontal application arrangement.

- configurable applicator options for tamp, swing, and wipe applications.

Reduce Expenses

Our lowest-cost robot eliminates your highest labor expense (turnover, onboarding, and training)

- Easy access to solenoids.

- OEM design for off-the-shelf replacement.

- Simple and efficient label and ribbon loading.

- Adjustable applicator assembly for easy maintenance.

Applicator Options

Configure your Panther FLEX labeling solution to meet production line needs or capabilities with any of the following standard or custom applicator options:

| Tamp | Wipe |

| Tamp Blow | Integrated Table |

| Front / Rear Swing | Custom |

Solutions for:

Senior Leadership

Your Challenges:

- Increased throughput in your operations.

- Reduce unnecessary expenses from chargebacks due to poor barcode quality.

Our Solutions:

- Up to 50% faster than competitor systems.

- Application speed matches line rate (up to 200 ft/min or more), so you label more products.

- Utilization of two Predators in tandem provides a Zero Downtime solution.

Operations Management

Your Challenges:

- Downtime due to increased operator interaction with labeling systems.

- Reduction of utility costs.

Our Solutions:

- Since labels are printed in the short direction, the system yields more labels per roll and requires fewer changeovers by operators = less downtime.

- System is all-electric, so no compressed air is needed, reducing your overall operating costs.

Operators & Technicians

Your Challenges:

- The number of label changeovers that occur during a shift, leading to increased downtime.

- Complex maintenance or service of the label applicator.

Our Solutions:

- Less need for label changeovers since more labels are available per roll = less downtime.

- System features modular components for ease in maintenance or parts replacement.

- No reciprocating parts or pinch points.

Image Gallery

Contact a Panther Account Manager

Ready to improve your production output and operational efficiency? Contact a Panther account manager today to learn how our labeling automation solutions will increase your throughput and improve your bottom line.